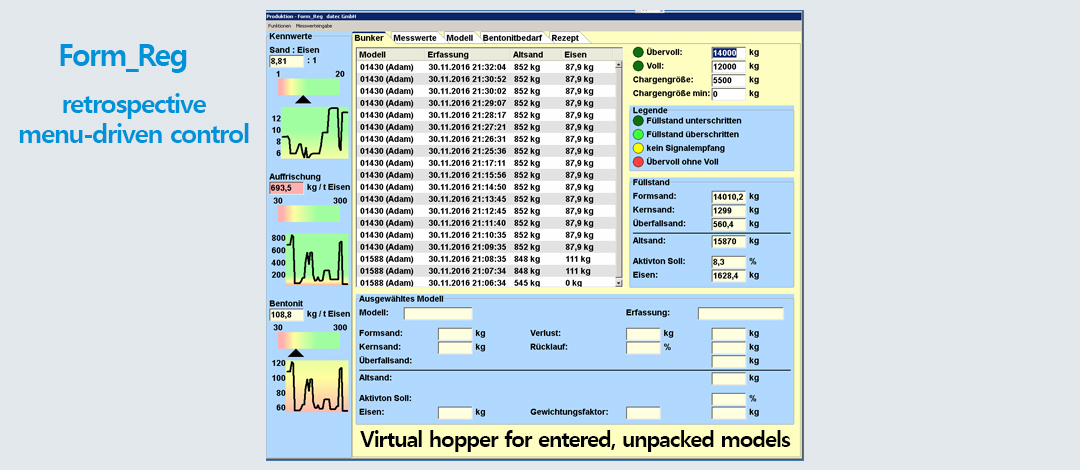

Retrospective menu-driven control

Form_Reg - Retrospective menu-driven control for your sand plant

High moulding sand quality

Independent of the sand temperature, the sand is moistured correctly for the cast.

Versatile application

The waterdosage can be equipped for each mixer type and can therefore be used universally.

Ethernet connection

Operational data and the state of operation are monitored and documented online.

Autonomous system

The electrode inside the mixer is in principle self-cleaning and limits the service expenditure.

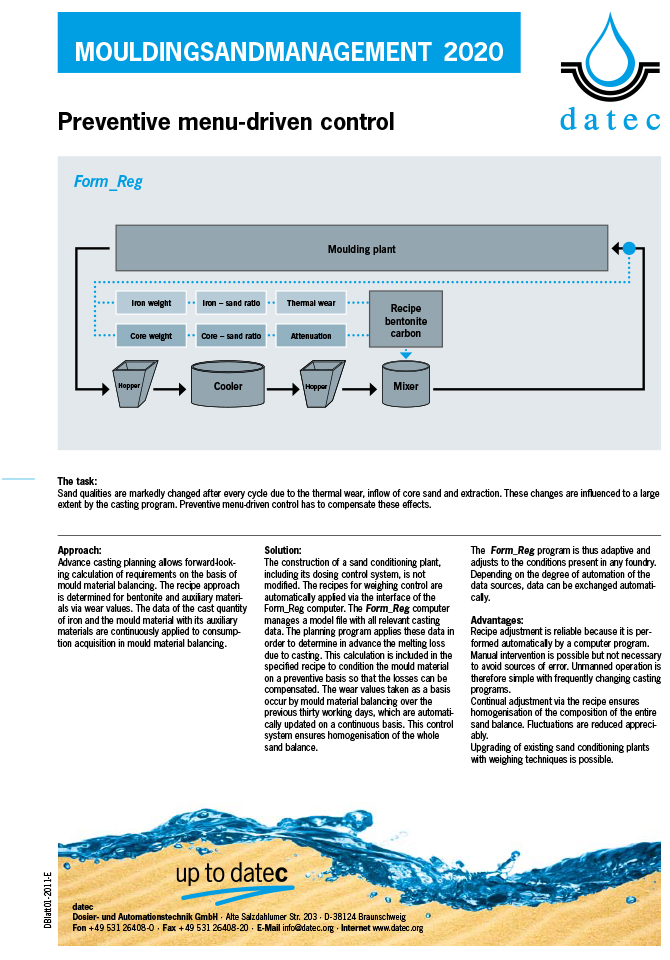

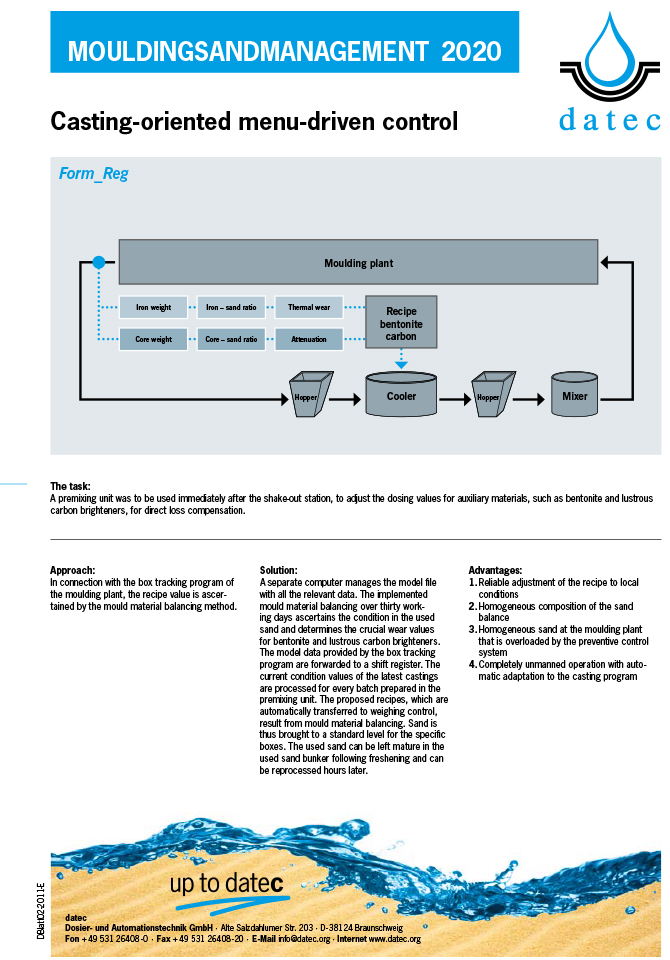

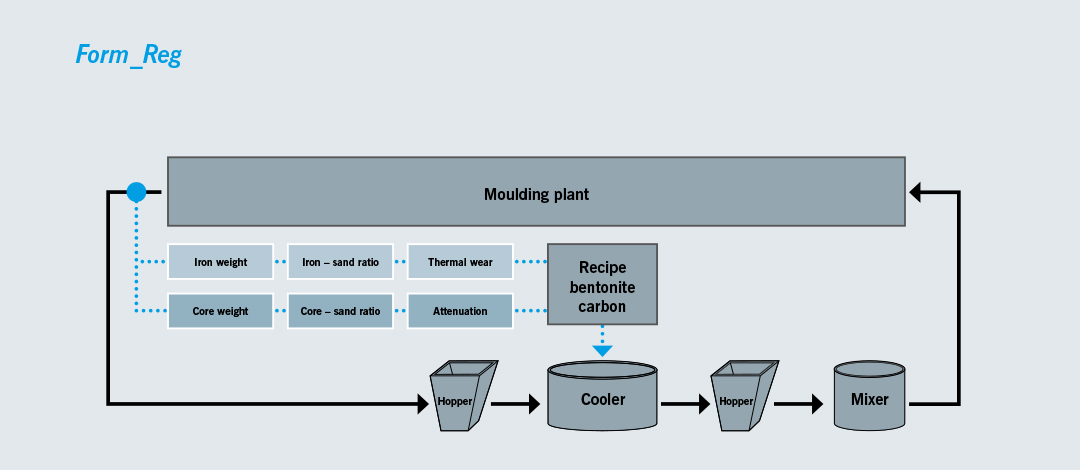

Task

A premixing unit was to be used immediately after the shake-out station, to adjust the dosing values for auxiliary materials, such as bentonite and lustrous carbon brighteners, for direct loss compensation.

Approach

In connection with the box tracking program of the moulding plant, the recipe value is ascertained by the mould material balancing method.

Solution

A separate computer manages the model file with all the relevant data. The implemented mould material balancing over thirty working days ascertains the condition in the used sand and determines the crucial wear values for bentonite and lustrous carbon brighteners. The model data provided by the box tracking programme are forwarded to a shift register. The current condition values of the latest castings are processed for every batch prepared in the premixing unit. The proposed recipes, which are automatically transferred to weighing control, result from mould material balancing. Sand is thus brought to a standard level for the specific boxes. The used sand can be left mature in the used sand bunker following freshening and can be reprocessed hours later.