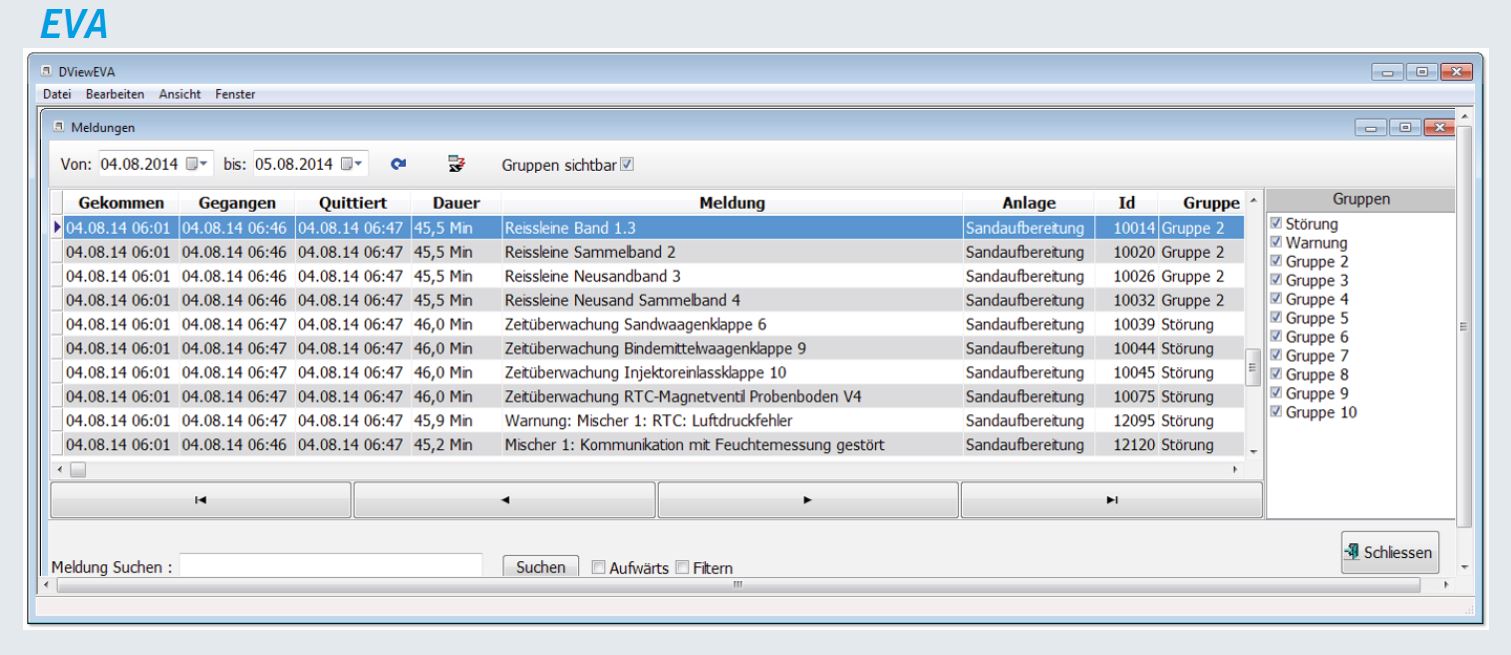

Fault analysis

fault_analysis - Improve your performance step by step

Critical analysis

Detailed interruption information provides information on potential for improvement

Objectivity

No subjective assessment and review but evaluation on the basis of the data situation

Faster problem solving

Documentation makes it easier to resolve faults

Task

Early recognition of faults in is very important with regard to the reliability of the system. Any faults should therefore be recorded and archived.

Approach

Through a joined-up approach to sand preparation and plant management, faults on all plant components can be recorded and collated in a database.

Solution

The fault analysis tool, EVA, sends fault notifications, documents them and archives any faults which have occurred in the plant components. EVA can do more than merely register the faults, it can also analyse the fault data. In this way, the number of faults, start, finish, duration and place of the fault can be identified in detail. The analysis of the data allows for prioritisation in fault troubleshooting.